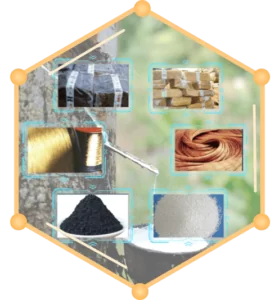

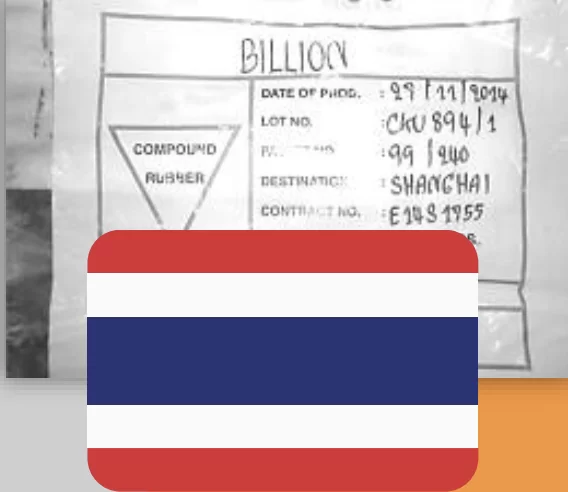

Shandong Hugerubber tire factory uses top global suppliers to ensure high-quality raw materials for all our tire manufacturing. With our reliable performance, you can be confident in purchasing a product manufactured with care and precision. Try our tires today to experience the difference and see why our customers trust in our products.

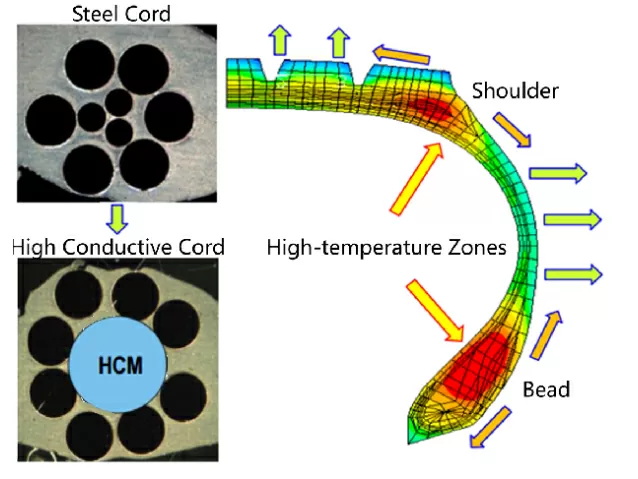

Better Heat Release

Better Airtightness

Better Stability

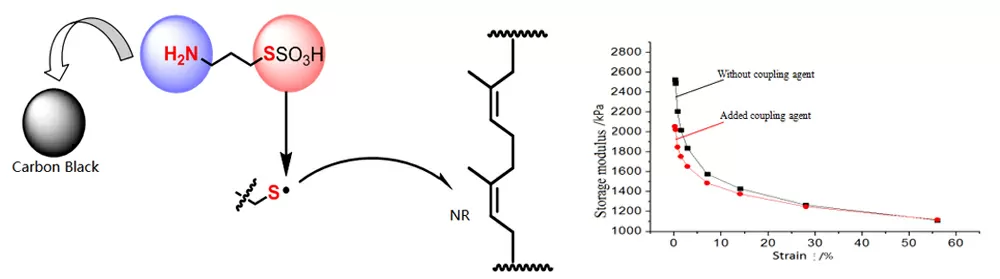

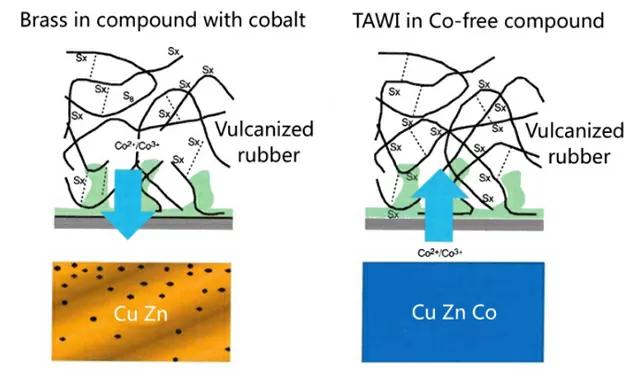

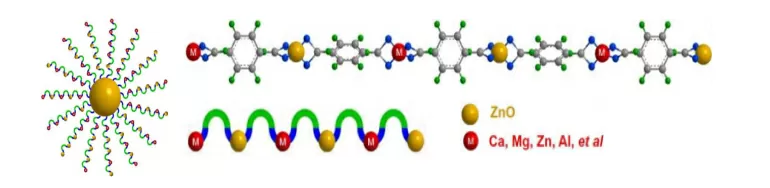

Stable Crosslink

Excellent Strength

BB430 Heavy Duty Mixer and mixing downstream Line from KOBELCO(JAPAN). The top facility of rubber mixer in the world, to be the best china tire factory.

We use the world’s best rubber mixer for our tires to ensure exceptional quality, durability, and safety. Our commitment to unparalleled excellence means that you can trust our tires are made with care and attention to detail using the best equipment available.

IHI is the leading manufacturer of precision calender lines in Japan.

Calender material with stable tension, uniformed rubberized compound and stable quality product.

IHI is the leading manufacturer of precision calender lines in Japan. Cooperated with IHI, to build the most advantage China Tire Factory.

Calender material with stable tension, uniformed rubberized compound and stable quality product.

High Efficiency screw design to ensure the extrusion tightness.

Triplex Extrusion to guarantee the correct tread for heavy duty TBR on two stage tire building machine

Extra Wide Die head to have right and left side wall at the same time.

Efficient improved tire uniformity and balance performance.

Pull through feeding and cutting to insure the high accuracy.

Steel breaker edge no spur to effectively improve the tire transition point stress and strain. GERMANY FISCHER Cord Cutting Lines

High Accuracy to improve the overall product quality.

High automation level, reduce the operator influence to cause the variation of the product.

High efficiency and can produce 160 tires/shift (8h)

The last step to get a new Frideric Tire by Yisheng Automatical Curing machine

100% automatic testing and evaluation on defect to avoid artificial missed judge.

In terms of Tire Dynamic Balance, Frideric Tire is better than normal brands, for example the size of 11R22.5 and 315/80R22.5 are 210g (while normal brands are 250g).

It is a KEY parameter for comfortability.

Micro-Poise / KOBE STEEL . LTD. Uniformity tester domestic truck tires manufacturer exclusive equipment, providing the guarantee testing for the steer truck tires of the buses exported to Europe

Testing-Holographic Laser Nondestructive Bubble Testing Machine, is used for Frideric TBR bubble checking, which is a strict testing usually used for light truck tires and Heavy Duty truck tires.

Improve tire quality and manufacture efficiency essentially

Excellent manufacturer capacity for OEM

To be worldwide excellent manufacturing TBR tire factory!

Copyright 2022 © All rights Reserved.

Heated Clothes | Steam Boiler | OTR Tire | Shower Glass Geomembrane |

WhatsApp us